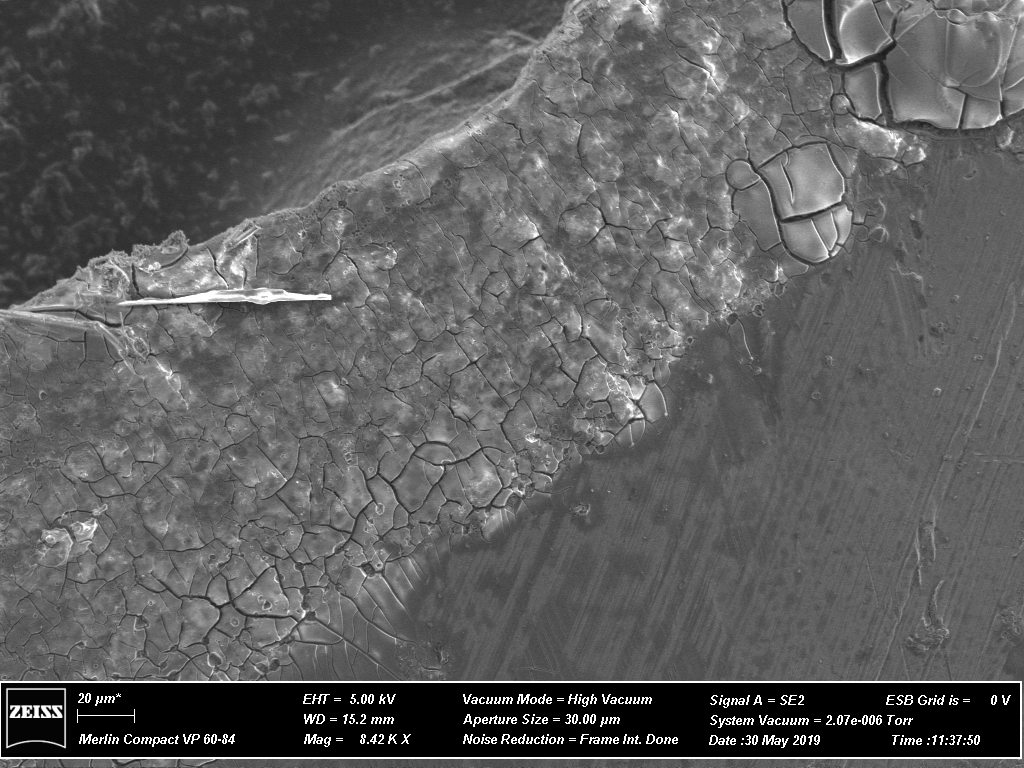

Aluminium Anode Interface

The aluminium anode interface is key to progressing rechargeable aluminium battery research, particularly in aqueous systems.

The aluminium anode interface is key to progressing rechargeable aluminium battery research, particularly in aqueous systems.

Aluminium batteries have great promise based solely on a theoretical basis due to its high capacity, however, this capacity is based on the assumption of an Al3+ charge carrying species. Due to the strong and stable oxide layer formed on aluminium metal, only a small number of electrolytes can effectively plate and strip aluminium at ambient temperatures. Currently ionic liquid or deep-eutectic solvent based electrolytes are commonly used which contain singly charged polyatomic aluminium complexes (e.g. AlCl4-), unfortunately these electrolytes are often corrosive and unstable in air or moisture. To develop the feasibility of aluminium batteries, progress should be made on the aluminium anode surface, to enhance the electrodeposition and enable the use of less corrosive electrolytes. To successfully produce a stable solid electrolyte interphase (SEI) layer on the aluminium surface could promote the use of more benign electrolytes and even enable aqueous electrolytes to be used.

Surface treatments using Lewis acidic [EMIm]Cl:AlCl3 ionic liquids have been demonstrated to improve the performance of aluminum anodes in aqueous systems. The Messinger lab has performed preliminary studies on this project and hope to develop it further with the assistance of a new undergraduate researcher in the Spring 2022 semester.